“Every possible avenue for human safety has been addressed by this company”

— Steve Goldner, Senior Project Engineer, with Humanetics Since 1973.

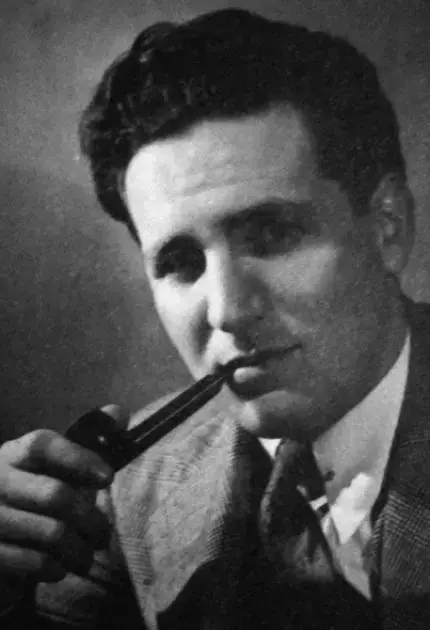

The father of anthropomorphic dummy testing

Our history begins with Samuel W. Alderson.

In 1952 Sam founded Alderson Research Laboratories,

the first of the companies that would become Humanetics. The company soon won a contract to create an anthropomorphic dummy for testing air and spacecraft ejection seats, helmets and restraint systems. Until then, the standard test protocols used flour sacks and sandbags.

In collaboration with Sierra Engineering Co., Alderson created the ancestor of all crash test dummies, appropriately named Sierra Sam. Later, Alderson would continue to develop and refine the concept as applied to automotive testing, leading to the familiar crash test dummy models still in use today.

Alderson passed away in 2005 at the age of 90. He was posthumously inducted into the National Inventors Hall of Fame in 2013 as the creator of a battery-powered prosthetic arm (patented in 1952), a human-equivalent dummy for testing radiation exposure (patented in 1961) synthetic wounds for emergency training (patented in 1962), and many other inventions promoting human health and safety.

However, by far his most consequential work was the invention and continuous improvement of automotive crash test dummies (patented in 1981), leading to an estimated 330,000 lives spared and millions of debilitating injuries prevented around the world.

The beginnings of automotive crash testing

From the first traffic death in 1869 until the 1950s, the automotive industry had paid little attention to safety, and any testing that manufacturers did perform was done with pigs and other animals or with human volunteers and cadavers.

In 1966, Ralph Nader’s seminal book Unsafe at Any Speed became a best-seller, and the U.S. Congress passed the National Traffic and Motor Vehicle Safety Act, which would lead to creation of the National Highway Traffic Safety Agency, or NHTSA, in 1970. These events and others demanded the development of crash test dummies that could more faithfully replicate human anatomical response to the full range of potential crash forces.

The first crash test dummies specifically for the automotive industry were Sam Alderson’s VIP series, introduced in 1968, which included average male, large male and small female “vehicular impact personnel” for frontal crash testing. In 1971, features of the VIP series along with parts from Sierra Engineering were incorporated by General Motors into the Hybrid I, offering improved biofidelity and greater repeatability of results.

With NHTSA sponsorship, further upgrades were incorporated into the Hybrid II series, which was introduced in 1973 and became the first dummy to be officially entered into the 49 CFR Part 572 standards for anthropomorphic test devices.

Advancing the state of the art

The VIP, Hybrid I and Hybrid II dummies were primarily useful for testing seatbelt designs at a time when over half of serious injuries and fatalities were due to head trauma. While the Hybrid II is still used to this day in aircraft testing, a more robust and sophisticated dummy was needed for automotive manufacturers to develop effective techniques for also preventing neck, thoracic, leg and other injuries, in humans of all ages, sizes and shapes.

This need led to the development of the Hybrid III series, introduced in 1978 and still required for frontal impact testing as specified in FMVSS 208 and part 572. Humanetics’ predecessor company, in partnership with the Society of Automotive Engineers, Ohio State University, and others, continued to advance the state of the art with Hybrid III improvements and expansion of the series to include large male and small female models. Child models were introduced to the series beginning in 1994.

Leading a global industry into the future

In 1999, Humanetics acquired the dummy development and manufacturing business of TNO Automotive, Europe's leading and largest dummy company, creating the first truly global dummy development and manufacturing company.

Throughout its history and continuing today, Humanetics has been key to the development and manufacture of a complete range of test dummies. These include side-impact, rear-impact, children, pedestrian models and more—plus the Test device for Human Occupant Restraint, or THOR, the next generation in dummy biofidelity, instrumentation, repeatability, durability and user-friendliness.

In the 21st century, Humanetics has greatly expanded its mission to encompass a complete range of technologies to protect life in motion.

For example, we provide test equipment for calibration and certification of test dummy instrumentation. Our iCrash Technology™ provides fully integrated onboard data acquisition systems, ensuing greater flexibility, improved repeatability, and reduced setup times during testing. We offer computer-aided analytics using virtual models that replicate our physical dummies in software, providing a cost-effective complement to physical product testing.

Our UltraFlat Overrunable robot, or UFO, enables testing of advanced driver assistance systems designed to avoid collisions by minimizing or correcting for human errors. It’s an extremely low-profile, remote-controlled platform that can be mounted with targets representing cars, cyclists, pedestrians, pets and more to test vehicle crash-avoidance sensors and controls. We also provide driving robots, accident reconstruction software, and much more.

Beyond automotive safety

Humanetics also continues to lead the industry in aerospace and military safety testing equipment, and we are actively expanding our safety mission into other realms.

For example, we have added HITEC Sensor Developments to our portfolio, providing hostile-environment sensors and strain gages for safety applications in marine, transportation, aerospace and other industries. We have also added Fibercore for its specialized fiber optic systems, used in a vast array of sensing and communication applications.

In growing our business, we have established offices and manufacturing facilities around the world, and we consult with many leading laboratories and research institutions to advance the cause of human safety.

We believe the project of creating a safer world never ends. In fact, we continually seek new beginnings. From our rich, proven history through to a future of continuous innovation, look to Humanetics as the human safety leader.